V-Guide

A v-guide is typically a urethane cord welded to the bottom of the belt longitudinally. It fits into a channel in the frame, drive pulley and tail pulley to help maintain belt tracking.

V-guides are especially important in applications where side-loading or -exiting exerts lateral forces on the belt; the conveyor is in a difficult to track location (e.g., mounted overhead); or in a wet environment.

Tracking

Tracking is keeping a conveyor belt centered on the frame, drive pulley and tail pulley. Tracking can be achieved a number of ways, including crowned pulleys, v-guiding and jacking screws. A belt that is not properly tracked can rub and become damaged along the edges. Every belt tracks slightly differently, so it is important to track the belt following the conveyor manufacturer’s instructions any time the belt is replaced.

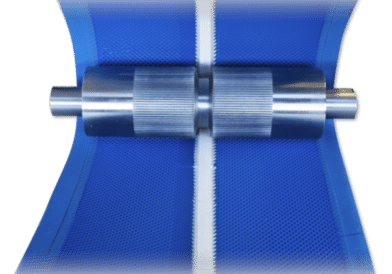

Timing Belt

A timing belt uses a toothed pulley to turn a toothed belt where the teeth are meshed together. When referring to a conveyor, it’s typically used for precise operation to avoid belt slip. Timing belts may also be used to connect a drive pulley to a top- or bottom-mounted gearmotor.

Tail Pulley

The tail pulley is contained within the belt and helps it to rotate freely around the ends of the conveyor. It is generally free-spinning, with bearings mounted either inside or on the ends of the tail pulley.

Nosebar Transfer

A nosebar transfer (or knife-edge transfer) is a smaller pulley used at one or both ends of a conveyor to reduce the space between conveyors and aid in small parts transfers between conveyors or to other machines. Even when conveyors with standard pulleys are placed extremely close together, there’s still a gap equal to the diameter of the pulley. By using a smaller pulley, that gap is reduced.

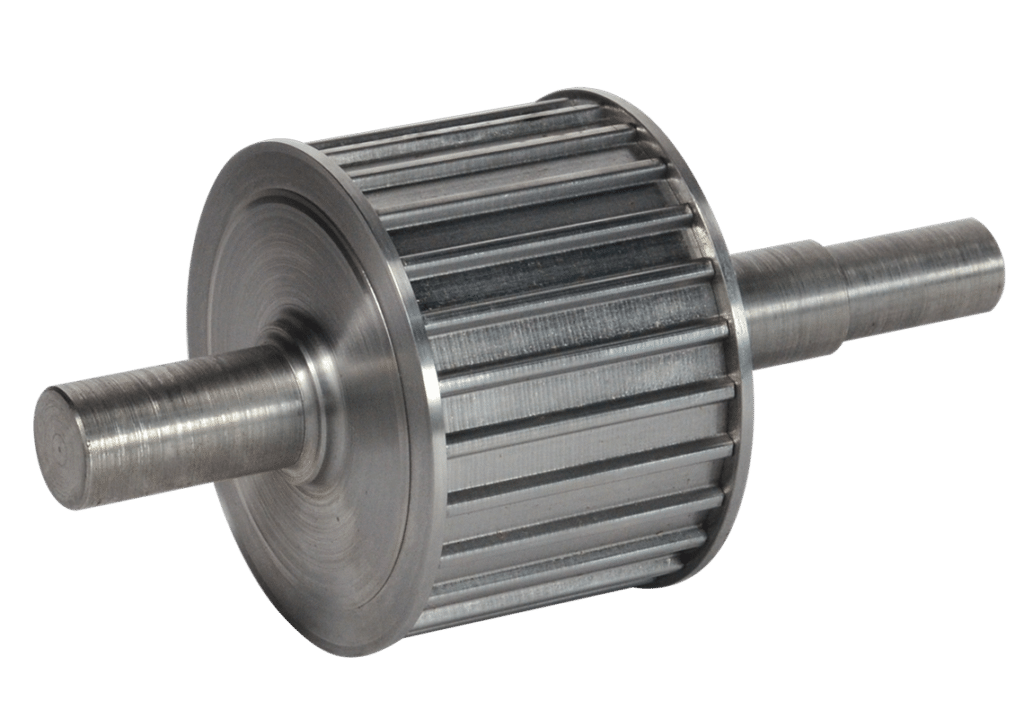

Knurled Pulley

A knurled drive pulley features a raised pattern machined into the outside of the drive pulley that adds traction when it contacts the carcass of the belt. Straight knurling (lines that run laterally across the drive pulley) allows the belt to wander slightly side-to-side (which is a natural occurrence due to the camber of the belt) without abrading the carcass of the belt.

Indexing Conveyor

An indexing conveyor moves a product at intervals based on the application requirements. It may move product a precise distance in order to align with another machine or operation or it may move product forward to a sensor. They may require many starts/stops per minute in high-speed automated applications or infrequently in manual operations.

Frame

The frame supports the belt, the drive pulley and the tail pulley. They are typically made of aluminum, steel or stainless steel.

It is important to choose a frame that is made as a single piece. Frames that are made of multiple pieces are susceptible to twisting or racking, which can lead to issues with tracking.

Feet Per Minute (FPM)

Feet Per Minute (FPM) is a standard measure of conveyor speed. It measures the number of feet the belt moves in one minute. Conveyor speeds are typically in the 5-200 FPM range.

Drive Pulley

The drive pulley rotates, which in turn causes the conveyor belt to rotate. In most cases, the drive pulley is located at one end of the conveyor located within the belt. It is supported by the frame and attached to the gearmotor, which causes it to rotate.

Many companies choose to use a crowned drive pulley, which is slightly larger in the center than on the ends. This helps to make tracking the conveyor easier.