Those transitions between conveyors can take many forms depending on the product being conveyed, the type of conveyor, and other considerations.

End-to-End Transfers

The most common type of transfer is the end-to-end transfer where product moves directly from the outfeed end of one conveyor to the infeed end of the next. Typically the outfeed is set slightly higher than the infeed so product “waterfalls” from one conveyor to the next.

For larger products (boxes, for instance), the is often a straightforward transfer without any additional considerations necessary. For smaller products, these transfers may require a transfer device if they’re not large enough to cross the gap created by the radius of the end of the conveyor.

Common transfer devices include nosebar tails (or knife edge transfer), driven transfers, roller transfers, and transfer plates.

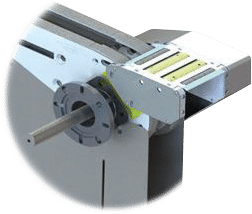

Nosebar Tails

Driven Transfers

Roller Transfers

Transfer Plates

A transfer plate is a simple plate affixed at the end of a conveyor that allows product to slide over the gap. They’re best suited for products with a very low coefficient of friction.

End-to-Side Transfers

When a 90° turn is required, an end-to-side transfer is common where product is fed from the end of one conveyor onto the side of the next. Again, larger products can usually cross the gap, but smaller products may require one of the transfer devices above at the outfeed of the first conveyor.

Guides or corner rollers are often used to ensure product transitions completely onto the second conveyor and is oriented in the proper direction. V-guides are recommended for any flat belt conveyor where product enters from the side to ensure the product doesn’t force the belt to mistrack.

Side-to-Side Transfer

Thanks to the low belt-to-frame ratio of low profile conveyors, side-to-side transfers are possible where guides are used to shift product onto a parallel conveyor. In modular plastic chain conveyors, these can be assisted by diagonal beams that allow two chains to make a slight turn and run very closely together for a short distance to facilitate the transfer.

Assisted Transfers

For some applications a special transfer device is required that provides some sort of an external assist either for all products or selected products (e.g., for rejection), these can include:

- Pushers

- Blowers

- Robots

- Divert gates

Such transfers are typically provided by an integrator or machine builder.

QC Conveyors’ Applications Engineers are experienced with many types of products and transfers and can help guide your choices. In some cases, testing may be required to ensure product is able to transition properly.