As one might expect, the food packaging industry works under stringent requirements for cleanliness and hygiene. All equipment must live up to strict sanitary standards, including, strict contaminant controls and the need for multiple daily washdowns. QC Conveyors’ HydroClean Series of food industry conveyors is designed with the most hygienic principles, and meets strict BISSC, and NSF guidelines.

Featuring stainless steel construction and encapsulated belt options, these food conveying systems are ideal for safe, quick cleaning that doesn’t affect production speed. Our conveyors for the food industry support a variety of packaging lines, from bakeries to dairies to meat processing facilities.

The HydroClean line is made to meet all food safety protocols and keep production lines as hygienic as possible. Design features including sealed bearings, slotted frames, and pull-pin disassembly help prevent the growth and spread of bacteria that can lead to contamination. Because they achieved BISSC and NSIF certification, our machines help packagers and processors meet the various food safety protocols they work under and ensure full compliance. Their superior performance also minimizes downtime and protects the integrity of food products.

Our conveyor solutions are built to support a wide range of food packaging operations. For example, our point-to-point modular plastic chain conveyors are the ideal solution for canning, bottling, and pre-packaged goods. They’re available in with stainless steel frames for maximum cleanability. Designed with modularity and flexible configurability in mind, our conveyors are the perfect fit for countless packaging processes.

Customers in the food packaging industry know they can depend on our solutions to provide them with the ultimate in durability, compliance, and ease of cleaning. We’ve helped many companies optimize their workflows with dependable, fully customizable, and scalable material handling equipment that meets all their needs. With our solutions in your facility, you’ll be ready for food safety audits now and well into the future.

If you’re ready to upgrade your food packaging line with sanitary, high-performance conveyors, contact us today to discuss your application and needs.

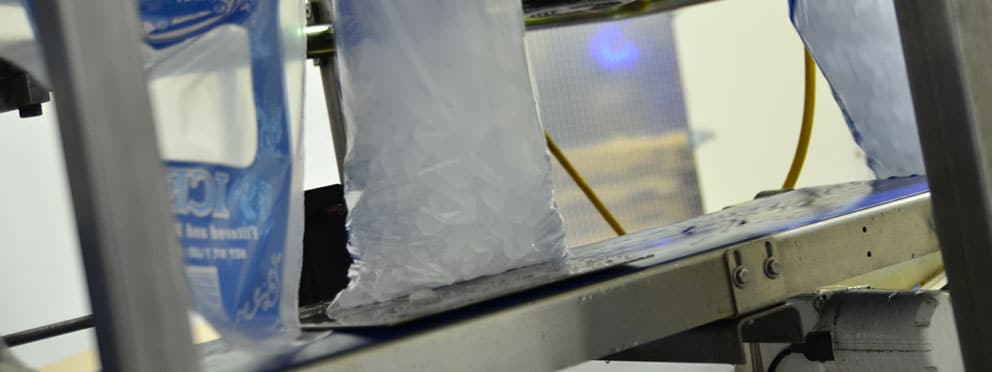

Queen City Ice, a company in the food packaging industry dedicated to making and packaging ice for retail and events, was one of the first to order a HC200 Sanitary Conveyor when they launched in 2015. They had such success with the first conveyor that they’ve since purchased additional product to speed their bagging process. As an SQF-Certified facility, Queen City Ice was drawn to HC200 conveyors due to their easy-to-clean design that requires no tools for disassembly. The conveyors must be able to operate in the cold, wet environment of an ice plant and withstand being washed down every day. The first conveyor replaced an older conveyor that required hours of disassembly and re-assembly each time it was cleaned. The HC200 conveyors can be completely disassembled or re-assembled in just a few minutes. It’s used in the bagging process for their 7 lb and 22 lb bags to move them from the fill point to the “ringer,” which places the metal ring that seals the top of the bag. “We wash down all of our equipment daily which can take its toll on some equipment,” said Bob Myers, who oversees the ice plant.”We have had no problems with the conveyor which is hard to find in such a harsh environment.” Another conveyor moves 50lb bags, used mostly for large events, through a heat-sealing machine. The bags are loaded and unloaded from the conveyor by hand. “We had conveyance concerns regarding the weight of our large bags of ice, operating in a wet environment, as well as ease of disassembly and re-assembly for cleaning,” said Dean Mazzaro, Director of Operations for Queen City Ice. “We have now been using the conveyors for the better part of two years with no issues!”

HC200 Food packaging and food handling Conveyors are stainless steel conveyors with sealed ball bearings, hex head fasteners, slotted frames and soft angles to promote draining. The unique pull-pin design redefines “in place cleaning” by making it fast and easy to disassemble and sanitize the conveyor. Sealed edge and totally encapsulated belt options are available for BISSC and NSF Certified conveyor needs.

Point-to-point systems are ideal for use in canning or bottling and are available with aluminum or stainless steel frames.

Gripper elevator systems can be used to raise product within a system. There are multiple wedge and box gripper options to choose from to protect and control product.

Alpine conveyor systems are ideal for temporarily removing product from your system to manage jams or change overs in the line.